- We are all audiophiles, who always seek for the best music reproduction. One of the most significant ways to enhance the quality of audio equipment is cable upgrades. However, audio cables from famous brands often come with high price tags, which is not suitable for the majority of Vietnamese audiophiles.

- Therefore, we establish Satin Audio with a vision to handcraft high quality customized audio cables at a competitive price for our domestic customers. We hope that Satin Audio products can satisfy the needs for cable upgrades of Vietnamese digital audio lovers.

- In addition to supply products for Vietnamese audiophiles, our vision is also to bring our high quality products at affordable prices to overseas market.

- Our brand, Satin, was named after a luxurious fabric material. Satin fabric is currently used to make the modern version of Vietnamese traditional Long Dress. Additionally, the letter ‘S’ in our logo represents the shape of our homeland, where the story of Satin Audio begins

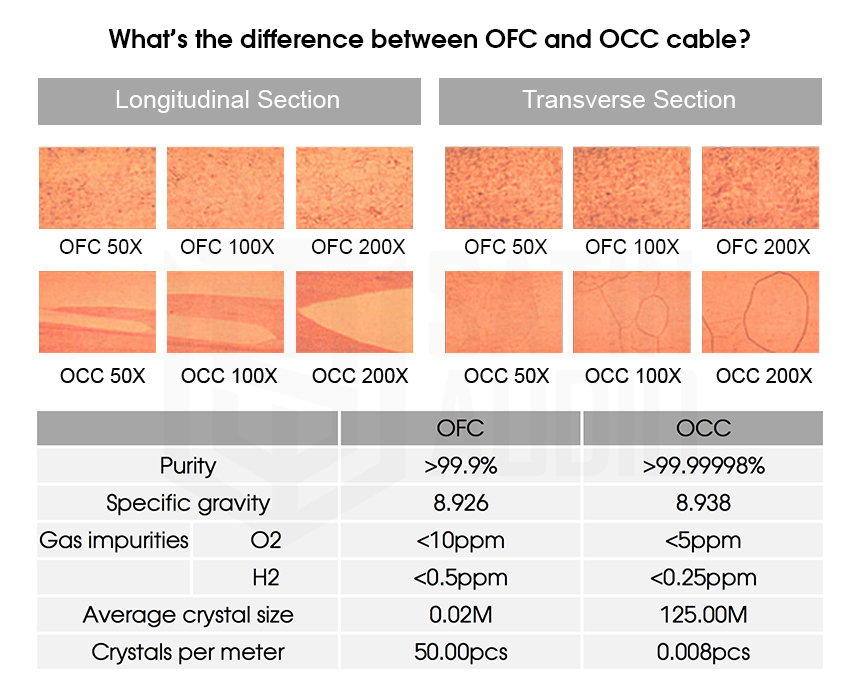

- OCC (Ohno Continuous Casting) is the most advanced casting technology developed to help defeat annealing issues and virtually eliminate all grain boundaries in copper or silver with a unique patented process. Satin Audio OCC wires are made at one of a very few factories in the world which can apply this advanced technology.

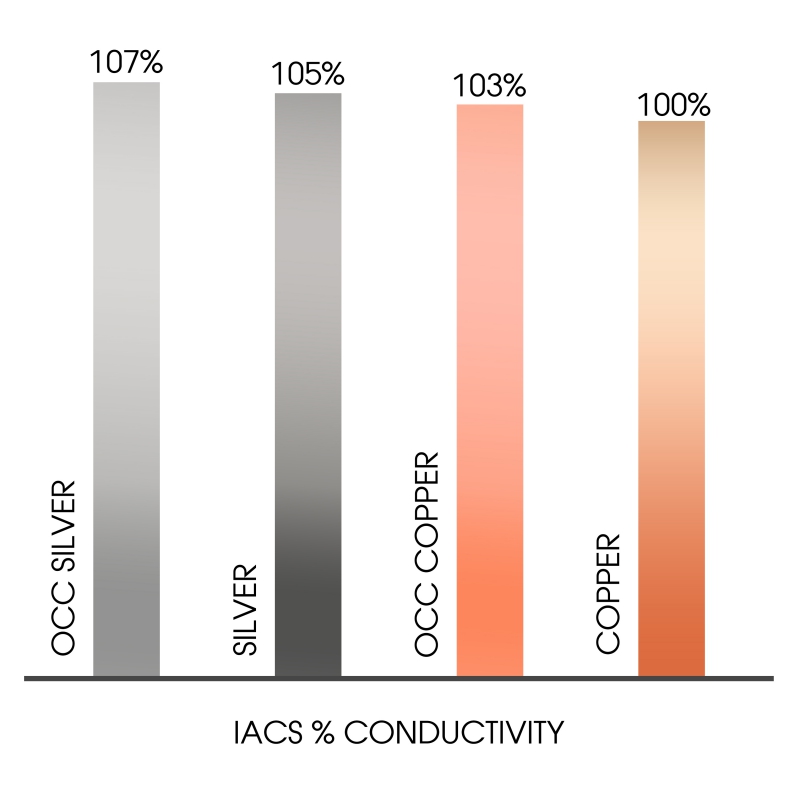

- OCC process helps to increase IACS % Conductivity of SIlver and Copper.

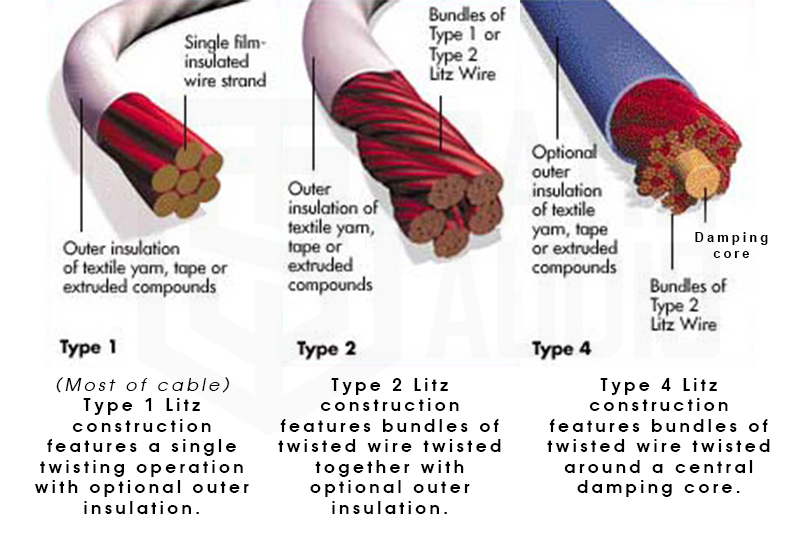

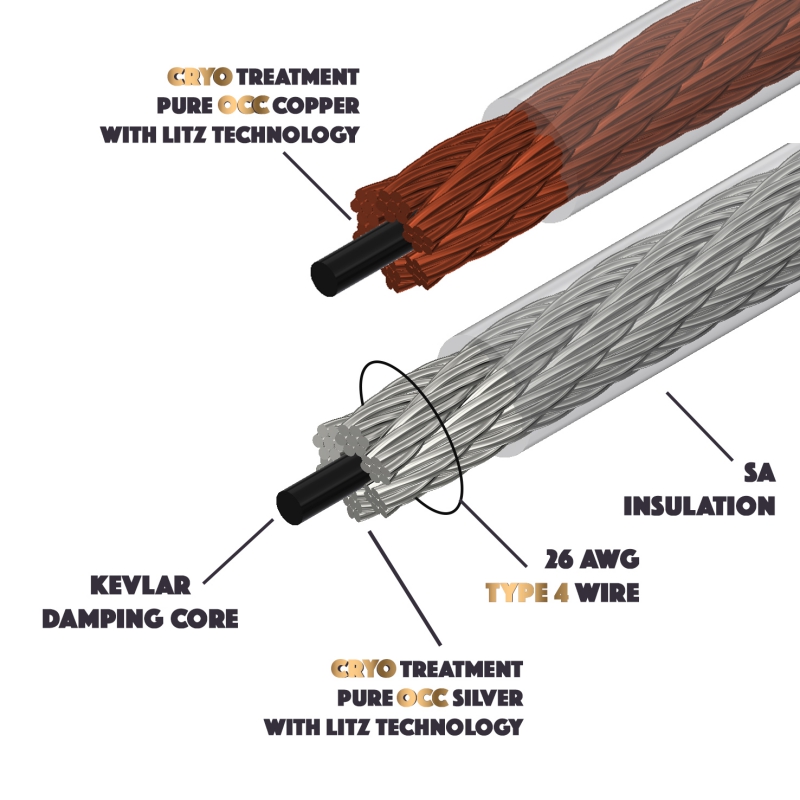

- Type 4 construction helps to keep the impedance constant and improve the LCR values of the cables in general. The construction of type 4 is that each wire is twisted together, and then these bundle of twisted wires continue to twist around a central Kevlar damping core.

- Litz is the technology designed to reduce the skin effect and proximity effect losses in conductors. Thanks to Litz, there is no possibility that the wires will be oxidizied and turns green.

- New SA insulation remains soft for the whole time and help the wires never turn hard or get broken after a period of usage.

- Kevlar is a heat- resistant and very strong synthetic fiber. Kevlar has many applications, such as bicyle tires to bulletproof vests, thanks to its high strength to weight ratio. Using Kevlar as damping core inside each strand of wire helps to minimize the vibrations and improve the durability of the cables.

- Cryogenic treatment is the freezing technology designed to enhance strength and durability of wires and also to improve the sound quality.

- This deep crygenic process, controlled by a computer, is developed specially for audio cables, slow cool down cycle from room temperature to the temperature of liquid nitrogen (-320 °F)

- Exclusive Satin Audio parts including 2.5mm balanced plugs, 3.5mm balanced plugs, Y-splitters and 2-pin connectors are used for all Satin Audio Medusa.

- All SA parts feature silver carbon fiber, silver anodized aluminum for shells and high quality Tellurium Copper pin (TeCu) & PEEK Insulation for connectors.

- There are two versions of Y-splitters with different hole sizes, which ensures that they fit with not just 4 braids, but also 6 or 8 braids.

- Also, for the best quality weld, we use high quality solders – Mundorf MSolder SUPREME (containing 9.5% silver and 0.1% gold, Made in Germany)